|

VR Resolver Rotasyn made by Admotec, equivalent of 1X-BRX Smartsyn Tamagawa seiki

Patented in USA and EC

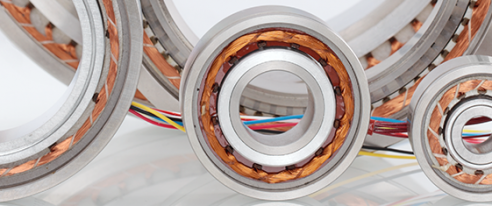

VR Resolvers Rotasyn made by

Admotec in Switzerland are unique brushless resolvers with excellent features.

|

The standard type of Rotasyn is "built-in type", frameless , or so called Pancake type.

Many users are using standard types of Admotec Rotasyns , RO Series, as they are. However, when some customers need resolvers with their required specifications, customized Rotasyns will be available. |

|

Admotec VR Resolver

Rotasyn Family

|

|

|

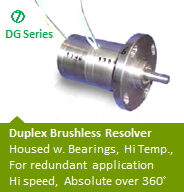

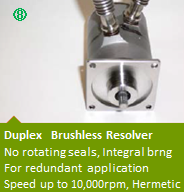

Among the the above stated Rotasyn Family, (1) RO Series, (7)(8) DG Series, can be called Standard types. Several items from these group can be delivered "Off the shelf" immediately on your orders. Rotasyn RO- 20110, 3620, 5032, 7557, in Stock : DG- 2010, 3620 and DG2-3620. (1) RO Series : depending on conditions, (1) Standard: Operating Temp. : -40°C to +135°C (2) High Temp.: Operating Temp. : -70°C to +200°C (7) DG Series depending on conditions, (1) Standard: Operating Temp. : -40°C to +150°C (2) High Temp.: Operating Temp. : -60°C to +230°C (10) Multispeed : Oper. Temp.: -200°C to +250°C |

|

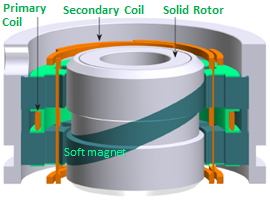

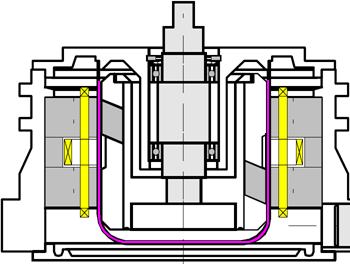

The hermetically sealed Rotasyn has a structure like the drawing shown left. Inside of the stator is covered with a stainless steel cup (colored pink) completely. The cup is attached to the stator inside by laser welding perfectly. In the case of conventional resolvers, the sealing is made on the rotating shaft side. Therefore. it can not be a perfect sealing and the sealing part wears as time passes by. Even in the case of Rotasyn, only the ones of which Stator side is sealed, and in addition, Rotor side has "buildt-in Bearing" structure, can be a perfect Hermetic Resolver. Such resolvers only can stand against corrosive gas or liquid. |

|

|

|

Examples of Application

Airplane: High reliability to protect the lives Racing car: Accelaration, high speed, vibration, shock Submarine: Rudder position feedback, Salt water. Steel Plants: Very high temperature and strong shocks Oil Drilling: Drill head control in harsh environment Nuclear Power: Nuclear radiation resistant |